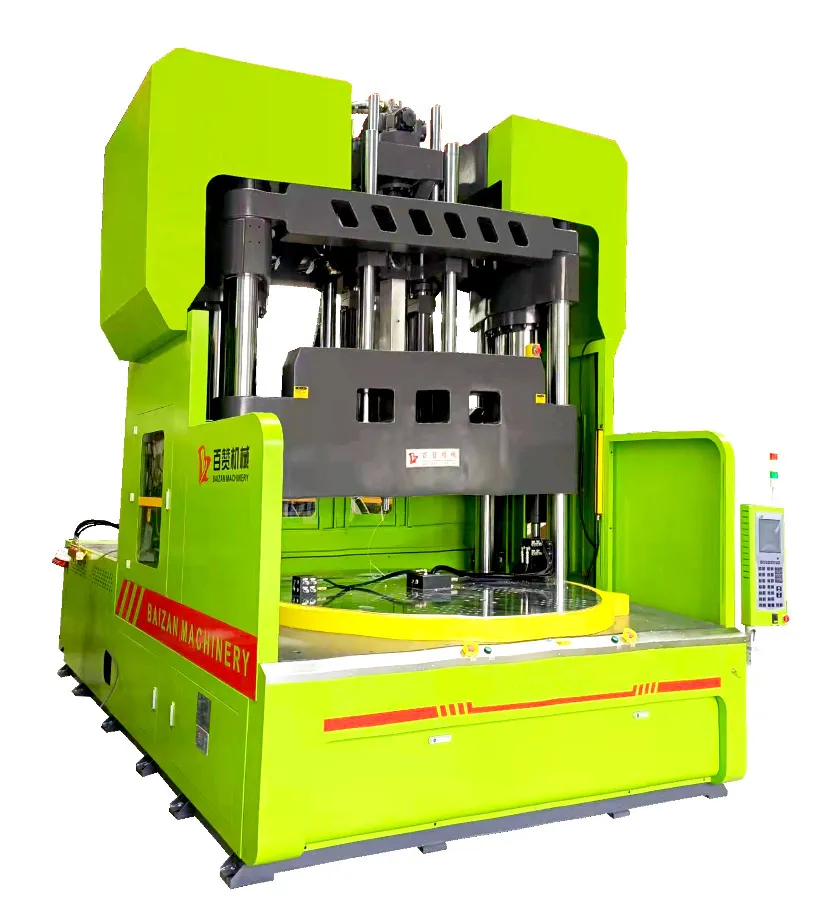

Product Name: Injection Molding Machine

Product Type: Hydraulic/ Electric/ Hybrid

Capacity: Varies from 50 to 5000 tons

Material Compatibility: Plastic, Rubber, Metal

Injection System: Single/ Multi-stage

Clamping Force: Varies from 50 to 5000 tons

Injection Rate: 100g-10kg/s

Mold Opening Stroke: Varies from 200 to 2000mm

Max Daylight: Varies from 500 to 4000mm

Platen Size: Varies from 400x400mm to 5000x5000mm

Control System: PLC or computer-controlled

Power Supply: 3-phase AC 380V/50Hz

Cooling Method: Water/oil cooling

Injection Pressure: Varies from 30 to 300MPa

Max Temperature: Varies from 150 to 400℃

Application: Manufacturing various plastic, rubber, and metal products such as automotive parts, household appliances, and electronic components.

| Condition | New | Showroom Location | None |

| Style | VERTICAL | Warranty of core components | 1 Year |

| Injection Rate (g/s) | 107 g/s | Core Components | Bearing, Motor, Pump, Gear |

| Machine Type | Hydraulic | Plastic Processed | LSR |

| Injection Weight (g) | 460 g | Ejector Stroke(mm) | 87 mm |

| Weight (KG) | 1044 kg | Ejector Force(kN) | 44 kN |

| Place of Origin | China | Theoretical Shot Volume(cm3) | 450 cm3 |

| Warranty | 1 Year | Screw Speed (rpm) | 0-346rpm |

| Key Selling Points | Injection Molding Machine | Screw diameter (mm) | 63 mm |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Home Use, Retail, Construction works , Energy & Mining, Advertising Company | Distance between Tie Bars | 860x 420mm |

| Type | Tube Head Injection | Open Stroke(mm) | 358 mm |

| Brand Name | Hommar | Power (kW) | 21.3 kW |

| Plastic Type | Thermoplastic | Transport Package | Customer's country |

| Voltage | 380V/220/415V | Language | According to customer's country |

| Automatic | semi-auto | Nozzle Projecting Template Size | ≥47 |

| Machine Color | White and red | After-sales Service Provided | Video technical support |

| Certification | CE IS09001 | Distance between Tie Bars | 860x 420mm |

| Quantity (sets) | > 1 | Lead time (days) | To be negotiated |

1.What is the role of the keba plc for injection moulding machine operator?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced keba plc for injection moulding machine products

The injection molding machine operator is responsible for setting up, operating, and maintaining the injection molding machine

This includes monitoring the machine's performance, making necessary adjustments, and troubleshooting any issues that may arise

The operator is also responsible for ensuring that the product meets quality standards and is produced in a timely manner

2.Can an keba plc for injection moulding machine be used for rapid prototyping?

No, an injection molding machine is not suitable for rapid prototyping

Rapid prototyping is a process that uses 3D printing technology to quickly create a physical model of a design

Injection molding machines are used to mass-produce parts from thermoplastic and thermoset materials

3.About keba plc for injection moulding machine production skills training

Injection molding machine production skills training is a comprehensive program designed to teach participants the fundamentals of injection molding machine production

The program covers topics such as machine setup, troubleshooting, safety, and maintenance

Participants will learn how to operate and maintain injection molding machines, as well as how to troubleshoot and diagnose common problems

The program also covers topics such as material selection, mold design, and process optimization

Upon completion of the program, participants will have the knowledge and skills necessary to produce quality parts with injection molding machines

4.About keba plc for injection moulding machine R&D capabilities

Injection molding machine R&D capabilities refer to the ability of a company to research, develop, and manufacture injection molding machines

This includes the ability to design and build custom injection molding machines, as well as the ability to develop and implement new technologies and processes

Companies with strong R&D capabilities are able to stay ahead of the competition and provide their customers with the most advanced injection molding machines available

5.About keba plc for injection moulding machine production equipment

Injection molding machine production equipment is used to produce plastic parts and components for a variety of industries

The injection molding process involves melting plastic pellets and injecting them into a mold cavity

The molten plastic is then cooled and ejected from the mold

Injection molding machines come in a variety of sizes and configurations, and can be used to produce parts ranging from small medical components to large automotive parts

6.How does the quality of the mold affect the final product in injection molding?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance

The quality of the mold affects the final product in injection molding in several ways

Poorly designed or constructed molds can lead to defects in the finished product, such as warping, cracking, or uneven surfaces

Poorly machined molds can also lead to poor part quality, as the plastic may not fill the mold properly or may not be able to be ejected from the mold

Poorly maintained molds can also lead to poor part quality, as the mold may not be able to maintain its shape or may have worn surfaces that can cause defects in the finished product

7.How are different shapes and sizes achieved in injection molding?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation

Different shapes and sizes are achieved in injection molding by using different types of molds

The molds are designed to create the desired shape and size of the part

The molds can be made from a variety of materials, including aluminum, steel, and plastic

The molds can also be designed to create complex shapes and sizes, such as those with multiple cavities or intricate details

The injection molding process also allows for the use of different types of plastic resins, which can be used to create parts with different colors, textures, and properties

8.Can an keba plc for injection moulding machine use a variety of molding materials in a single production cycle?

Yes, an injection molding machine can use a variety of molding materials in a single production cycle

Injection molding machines are designed to be able to handle a wide range of materials, including thermoplastics, elastomers, and thermosets

The machine can be programmed to switch between different materials during the production cycle, allowing for the production of complex parts with multiple materials

9.What are the advantages of using an keba plc for injection moulding machine?

We have a wide range of keba plc for injection moulding machine customer groups and establishes long -term cooperative relationships with partners

The countries we provide services include

1

Cost-Effective: Injection molding is one of the most cost-effective manufacturing processes due to its high production rate and low material waste

2

Versatility: Injection molding machines can be used to produce a wide variety of parts and products with different shapes, sizes, and materials

3

Automation: Injection molding machines are highly automated, allowing for a high degree of repeatability and accuracy

4

Durability: Injection molded parts are highly durable and can withstand extreme temperatures and pressures

5

Efficiency: Injection molding machines are highly efficient, allowing for quick production of large quantities of parts

10.What is the role of software in controlling and monitoring an keba plc for injection moulding machine?

Software plays an important role in controlling and monitoring an injection molding machine

It is used to control the speed, pressure, temperature, and other parameters of the machine

It can also be used to monitor the performance of the machine, detect any faults, and provide feedback to the operator

Additionally, software can be used to store and analyze data from the machine, allowing for better optimization of the injection molding process

11.How does the rate of injection affect the final product?

The rate of injection affects the final product in several ways

A slower rate of injection will result in a product with a higher molecular weight, while a faster rate of injection will result in a product with a lower molecular weight

Additionally, a slower rate of injection will result in a product with a higher viscosity, while a faster rate of injection will result in a product with a lower viscosity

Finally, a slower rate of injection will result in a product with a higher degree of crystallinity, while a faster rate of injection will result in a product with a lower degree of crystallinity

12.How do temperature and humidity affect the operation of an keba plc for injection moulding machine?

Our keba plc for injection moulding machine products have competitive and differentiated advantages, and actively promote digital transformation and innovation

Temperature and humidity can have a significant effect on the operation of an injection molding machine

High temperatures can cause the plastic to melt too quickly, resulting in poor quality parts

High humidity can cause the plastic to absorb moisture, which can cause the plastic to become brittle and crack

Low temperatures can cause the plastic to cool too quickly, resulting in poor part quality

Low humidity can cause the plastic to become too dry, resulting in poor part quality

13.Can an keba plc for injection moulding machine produce products with multiple colors?

Yes, an injection molding machine can produce products with multiple colors

This is done by using a process called two-shot injection molding, which involves injecting two different colors of plastic into the same mold

14.How can the clamping force of an keba plc for injection moulding machine be calculated?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market

The clamping force of an injection molding machine can be calculated using the following formula:

Clamping Force (kN) = (Mold Cavity Area (cm2) x Cavity Pressure (MPa)) / 1000

Where Mold Cavity Area is the total area of the mold cavity, and Cavity Pressure is the pressure of the molten plastic material inside the mold cavity

15.What types of materials can be used in an keba plc for injection moulding machine?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities

Common materials used in injection molding machines include thermoplastics, thermosets, elastomers, and metals

Thermoplastics are the most commonly used materials, as they are easy to process and can be recycled

Examples of thermoplastics include polyethylene, polypropylene, polystyrene, polyvinyl chloride, and nylon

Thermosets are materials that are cured and hardened during the injection molding process, and are not able to be recycled

Examples of thermosets include epoxy, polyester, and phenolic

Elastomers are materials that are flexible and can be used to create rubber-like parts

Examples of elastomers include silicone, polyurethane, and thermoplastic elastomers

Metals can also be used in injection molding machines, but are not as common as thermoplastics

Examples of metals used in injection molding include aluminum, brass, and steel

16.About the scale of keba plc for injection moulding machine factory

Injection molding machine factories vary in size and scale

Some factories may only produce a few machines per year, while others may produce hundreds or even thousands of machines per year

The size of the factory will depend on the size of the machines being produced, the number of machines being produced, and the demand for the machines

17.How does an keba plc for injection moulding machine compare to other types of molding machines?

As one of the keba plc for injection moulding machine market leaders, we are known for innovation and reliability

Injection molding machines are the most commonly used type of molding machine

They are used to create plastic parts by injecting molten plastic into a mold

Injection molding machines are highly automated and can produce parts quickly and accurately

They are also capable of producing parts with complex geometries and intricate details

Compared to other types of molding machines, injection molding machines are more expensive and require more setup time, but they are capable of producing higher quality parts with greater precision

18.About keba plc for injection moulding machine payment method

Injection molding machines can be paid for in a variety of ways, including cash, check, credit card, and wire transfer

Depending on the size of the purchase, some suppliers may also offer financing options

It is important to discuss payment terms with the supplier before making a purchase

Leave A Message

We gain many good reputations and lasting trust from all customers by professional and high efficiency service and high quality standard qualified products. feel free to communicate your ideas and ask lots of questions.

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.