Are you looking for a machine dedicated to the production of plastic eyeglass frame?

Plastic eyeglass frame injection molding machine can use PE PP PS to produce plastic eyeglass frame ,As a professional injection molding machine manufacturer, we have been selling affordable plastic eyeglass frame machines to customers around the world. We have various models of injection molding machines for you to choose from, which can meet your individual needs. We have a professional overseas sales team and technical engineers

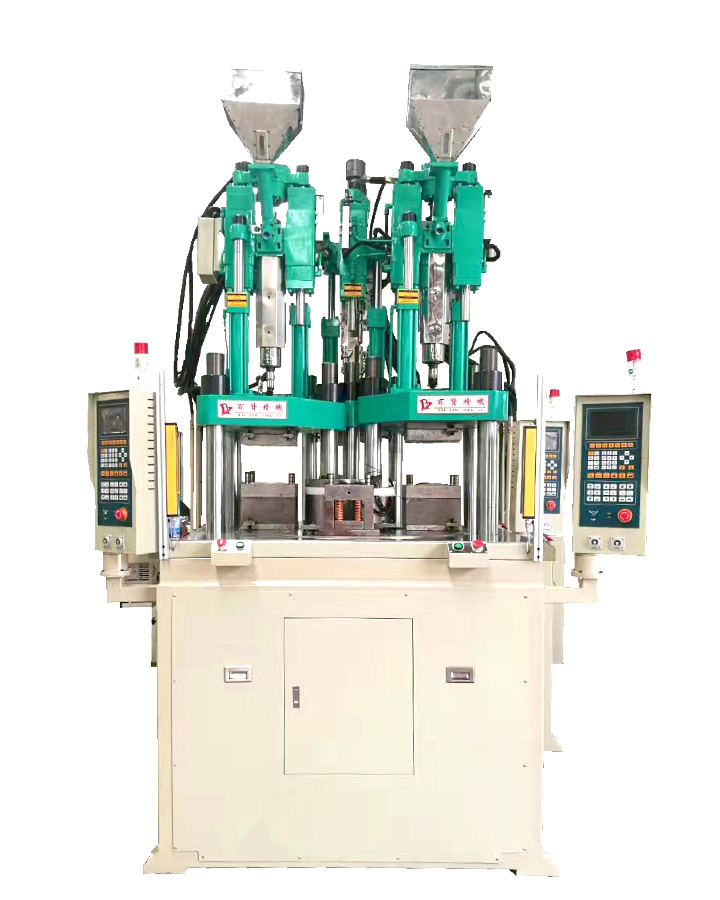

Products Description

Clamping Force | 180T |

Plastic Type | Thermoplastic |

Machine Type | Vertical Plastic Injection Molding Machine |

Screw Diameter | 42mm |

Screw Stroke | 160mm |

Machine Dimesions | 2730mm*2030mm*3040mm |

* Vertical clamping, vertical injection.

* Compact design requires less floor space. Makes the take-out process more easilier.

* Suitable for multi-purpose injection molding. Excellent for insert molding.

* Optional Feature : High-speed injection unit utilizing closed-loop system.

Combining Advantages

Combining advantages of hydraulic and electric machines and highlighting high energy savings, fast response, high precision and high efficiency.

Saving Energy

Servo-motor-driven g ear pump and screw regulated b y servo controller,closed-loop control of flow and pressure, accurate multi-stage speed and pressure control of injection and clamping and plasticizing.

High Performance

Suitable for injection molding of ultra-thin and high-precision products .

Injection response time ≤ 20 ms , injection speed up t o 1000 mm/s, part weight tolerance ≤0.5%.

PLC |

Brand: Porches on |

Original: TAIWAN |

Features: High Precise Control,High Sensitive Response ,TFT Color Display,Language:Portugal,English,Chinese |

Servo motor |

Brand: INOVANCE |

Original: CHINA |

Features: Save power by 60% and low noise |

Position Transducer |

Brand: Gefran |

Original: Italy |

Features: High Precise Control |

Directional Valve |

Brand: PINGZHONG |

Original: CHINA |

Features: High sensitive response |

Applications

Specification

Mold | Unit | HM-V180Z6-3C | |||

注射装置 Injection Unit | Screw Diameter | mm | 42 | 42 | 42 |

Screw Stroke | mm | 160 | 160 | 160 | |

Theoretical Shot Volume | cm³ | 221 | 221 | 221 | |

Injection Molding Quality | g | 206 | 206 | 206 | |

oz | 22 | 22 | 22 | ||

Max.Injection Pressure | Mpa(kgf/cm²) | 140(1428) | 140(1428) | 140(1428) | |

Injection Rate | cm³/s | 110 | 110 | 110 | |

Screw Speed | r.p.m | 0-250 | 0-250 | 0-250 | |

合模装置 Mold Clamping Unit | Clamping Force | KN(tf) | 1164(180) | ||

Clamping Stork | mm | 250 | |||

Min.Mold Thickness | mm | 220 | |||

Max.Open Distance | mm | 470 | |||

Space Between Columns | mm | 1040*765 | |||

Max.Size of Mold | mm | 300*250 | |||

Plate Size | mm | 1400*1125 | |||

Distance of Product Out of Mold | mm | 65 | |||

Ejector Force | KN(tf) | 1720(17.5) | |||

QTY of Ejector | pcs | 1*2 | |||

其他 General | System Pressure | Mpa(kgf/cm²) | 13.7(140) | ||

Motor Power | kw(HP) | 14*3 | |||

Electric Power | kw | 4.2*3 | |||

Temperature Stage | 5*2 | ||||

Mechanine Dimesions | mm | 2730*2030*3040 | |||

Machine Weight | tf | 11 | |||

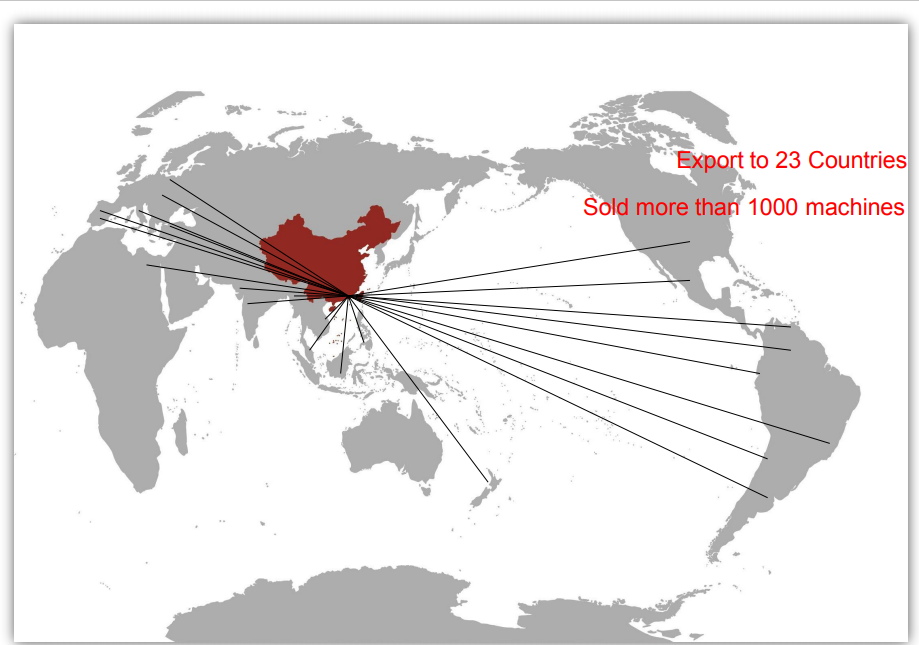

Company Profile

About us

Hommar Industry Co., LIMITED is engaged in developing and manufacturing plastic injection machine and integrating peripherals and providing one stop source for customers for more than 20 years. Hommar has served more than 2000 customers not only with single process service but finished product from concept to packing and exports products to more than 30 countries, including 50 World Fortune 500 companies from electronics, telecommunication, home appliance, kitchen appliance, textile, shoes, automobile, machinery, gift, lighting, toys, health &medical, packing and so on.And we gain a lot of good reputations and lasting trust from customers by professional and high efficiency service and high quality standard qualified products all over the world. Our headquarter and the first factory is located in Dongguan, Guangdong with 22000 square meters floor and the second factory is located in Jiangmen, Guangdong with 60000 square meters floor.

Selling more than 1000 machines every year

30+ million USD Sales turnover in 2018

Working with more than 200 listing corporations.

Always focus on upper-class quality machines

Developing at least 15 new machines every year

Professional and sincere marketing team +professional and flexible engineer team+ professional and experienced production team.

Exhibition

Our Customers

Certifications

Hommar is a professional manufacturer of vertical injection molding machine since 1998.

Developing at least 15 new machines every year.

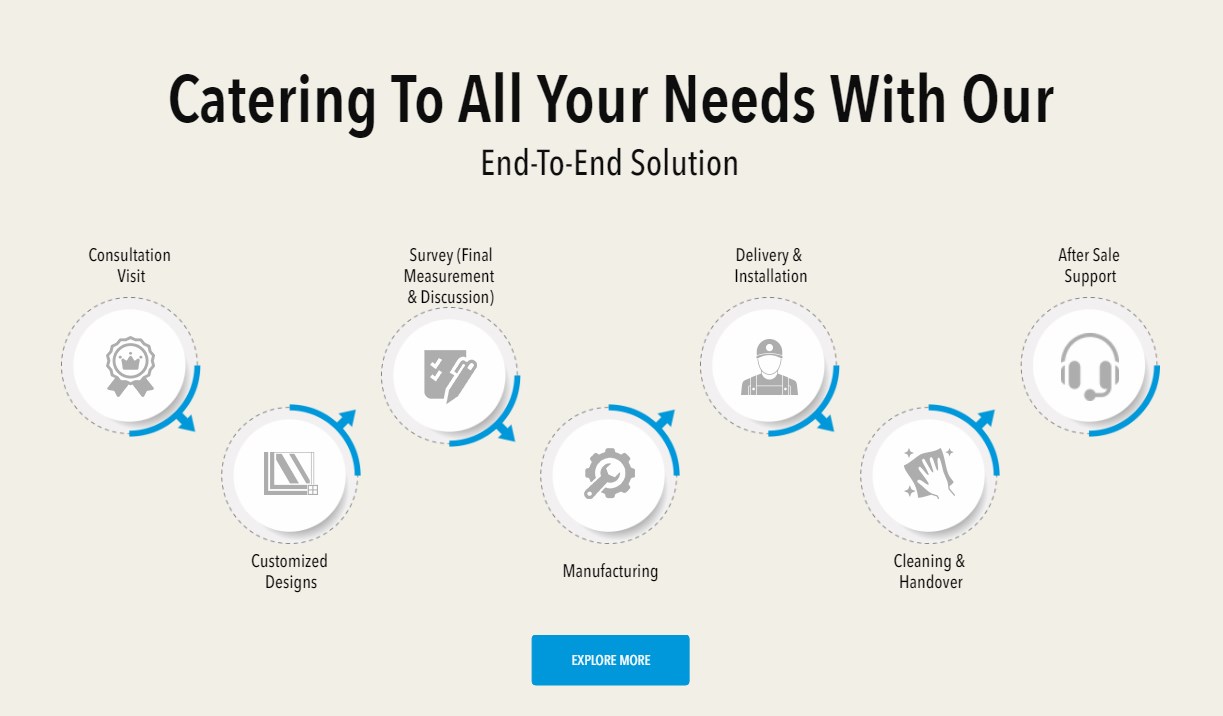

Packing and Delivery

Packing has been added with moisture-proof and rust-proof protection measures according to the characteristics of the equipment.

All the goods delivered by us have strong packing suitable for long distance transportation, multiple handling and handling.

The packaging structure of export products is scientific and reasonable to ensure the safety and reliability of the products under the conditions of automobile transportation, railway transportation, ocean transportation and various loading and unloading conditions.

Leave A Message

We gain many good reputations and lasting trust from all customers by professional and high efficiency service and high quality standard qualified products. feel free to communicate your ideas and ask lots of questions.

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.